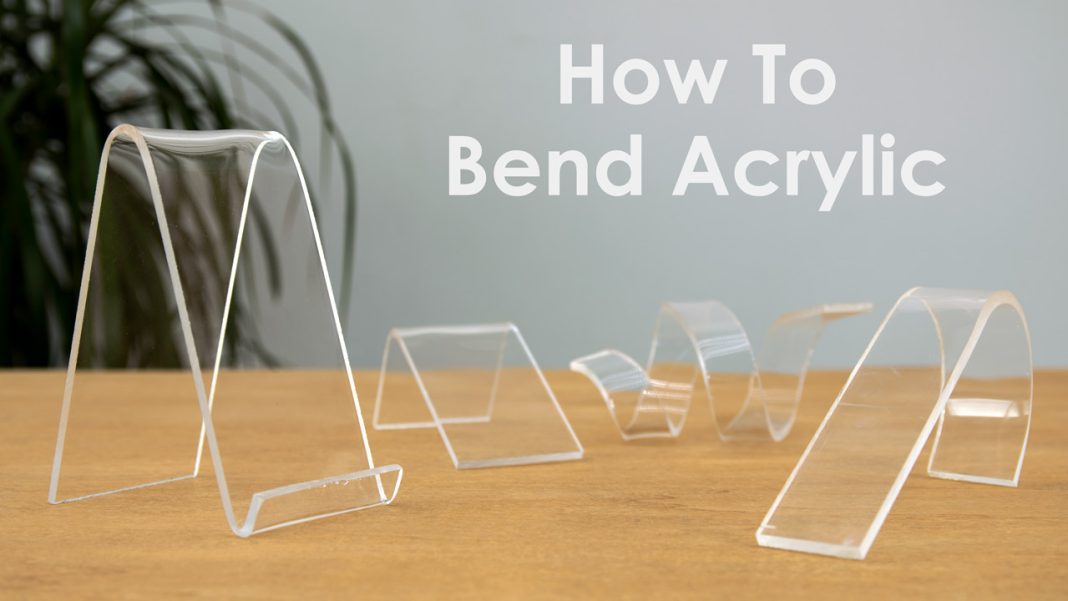

To set up your plastic or acrylic sheet to bend simple curves for your miniature and model projects you need to first remove the protective covering from the material you wish to bend.

Bend large acrylic sheet.

Use long thin 1 inch or so in width test strips to practice your technique and learn how your particular heat source affects your chosen thickness of plastic.

Leave the acrylic in a cool dry area for several minutes to cool.

Once it is at the required angle use a bending fixture to hold the sheeting in place.

Gather the supplies you need in order to bend the acrylic with a heat gun.

Thermoforming can range in complexity from manual operations to highly automated large scale ones.

Optix acrylic sheet is a lightweight impact resistant optix acrylic sheet is a lightweight impact resistant transparent material that is a great replacement for glass in many applications.

Plexiglass sheets offer similar transparency to glass but they are more durable and relatively shatter proof.

The freight for 1 2 x 48 x 96 sheet of gray acrylic is 90 00 sometimes there is a 65 00 pallet charge.

Cutting tools such as a dremel saw circular saw table saw and or razor knife.

Once you go past a 48 x 96 sheet costs can skyrocket.

Thermoforming refers to the process of heating and shaping a plastic sheet on a mold.

Acrylic pvc plastic strip heater 110v bending machine 24 inch 60cm manual hot heating bender tool 1mm 6mm thickness for sign making 4 0 out of 5 stars 3 119 99 119.

A vise and clamps.

In the case of a sharp edged design remember to bend it with the cut edge on the outside.

The freight on a 1 2 x 48 x 96 sheet of clear acrylic is 0 0.

A heat gun which is an electrical tool that heats and softens a variety of materials.

Please keep in mind the bigger and thicker the part is the more it cost to bend.

Acrylic sheeting can be used to replace window panes protect surfaces or even hold items as shelving.

Acrylic sheets also referred to as plexiglass or plexiglas are often used as an alternative to glass sheeting.

Sheet of acrylic large enough for your needs.

Thermoforming offers processing advantages over competitive processes such as blow molding and injection molding.